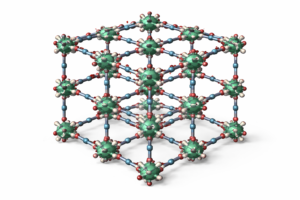

MOFs are porous crystalline materials formed by linking metal ions with organic molecules into highly orderly three-dimensional structures. This unique architecture allows researchers to precisely control pore size and chemical functionality, making it possible to tailor the materials for very specific technological tasks.

“These unique properties give the materials exceptional potential in environmental applications, including carbon dioxide capture, gas storage, wastewater treatment, separation processes, and catalysis, where they act as highly selective molecular filters,” explains Dr Samy Yousef, a researcher at KTU.

Because MOFs operate at the molecular level, they are seen as particularly promising in addressing pollution and climate change challenges. Their potential, however, extends well beyond environmental technologies.

“In addition to environmental applications, metal–organic frameworks are also regarded as promising platforms for optical sensing, controlled drug delivery, biomedical technologies, and antioxidants,” notes KTU researcher.

This broad range of potential uses, combined with the ability to adapt the materials to specific tasks, is one of the main reasons why MOFs have remained at the centre of intensive scientific research for more than two decades.

Advanced Materials Still Confined to Laboratories

“Laboratory-scale production does not take into account many aspects that are crucial at the industrial level, particularly secondary waste management, solvent regeneration, and long-term material stability,” says Dr Yousef.

As a result, MOFs are still typically produced only in small quantities and are mainly used in scientific research or highly specialised applications.

Building on the process sequences used in laboratory synthesis, the KTU researcher designed integrated production lines for the industrial-scale manufacture of MOFs. To do this, he selected commercially available industrial equipment and assessed individual production stages, their integration, and overall production capacity.

The analysis included a detailed assessment of raw material, chemical, and electricity consumption, as well as labour costs. Calculations were carried out under the economic and legal conditions applicable in Lithuania, allowing a realistic evaluation of whether such production lines could operate in practice.

The study showed that, depending on the production method chosen, industrial-scale manufacturing of MOFs can be financially viable, with investments in such production lines potentially paying off within a relatively short period of time.

“I believe that within a few years we will see fully operational production lines with capacities of several tonnes,” predicts Dr Yousef. In that case, MOFs could begin to appear in everyday technologies, although mostly indirectly.

“People would most likely encounter these materials in everyday devices such as air purifiers, building ventilation systems, or water filters, where their large surface area enables them to trap pollutants and toxins very efficiently. In most cases, MOFs would operate behind the scenes, improving performance, efficiency, and sustainability,” says the KTU researcher.

The scientific article Techno-economic assessment of scale-up of metal-organic framework production can be found here.